Lift stations are pump stations that transport wastewater from a lower to a higher area. These are affordable alternatives that reduce the capital construction costs of the traditional gravity flow sewer systems. With a lift station, you won’t have to spend on excavation or end up digging deeper than 10 feet on a site for the sewer line.Is there a way for you to monitor lift stations remotely and connect them to a central data source? Find out what a lift station can do for your construction site or an area that doesn’t have enough depth for a sewer line. Plus, the technology available to you to monitor the lift station’s performance and repairs.

Lift stations are pump stations that use a collection system to move sewage or wastewater from a lower to a higher elevation. They are usually installed in places with too much pipe depth or low-lying locations. The stations normally transport the wastewater from residential and commercial areas to a proper wastewater treatment plant. Steel lift stations last between 15 to 20 years and last longer with proper care and maintenance.

How does a lift station work?

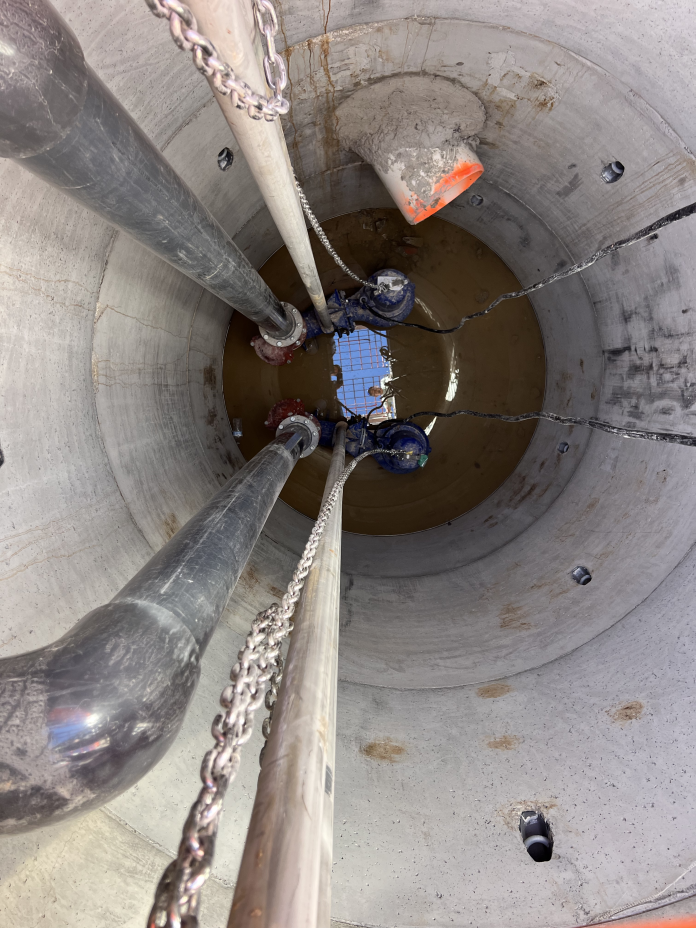

So how exactly do these lift stations work? There are two types to consider. The first is the dry well, composed of two collection areas: the pit or wet well, where wastewater is collected, and a dry well composed of the pumps, equipment, and controls that transport the water. The latter parts of the equipment are found in a separate location underground. The wet well on its own makes it more accessible for maintenance and inspection. The second type of lift station is the single submersible wet well. It’s the most popular and affordable structure with an opening submerged inlet and it operates underwater. All components are installed inside or adjacent to the single wet well. It’s cheaper compared to dry well stations and requires less frequent pump maintenance in its operations.

Wastewater lift stations are facilities designed to move wastewater from lower to higher elevations through pipes. Key elements of lift stations include a wastewater receiving well (wet-well), often equipped with a screen or grinding to remove coarse materials; pumps and piping with associated valves; motors; a power supply system; an equipment control and alarm system; and an odor control system and ventilation system. Lift station equipment and systems are often installed in an enclosed structure. They can be constructed on-site (custom-designed) or pre-fabricated.

Lift station capacities range from 76 liters per minute (20 gallons per minute) to more than 378,500 liters per minute (100,000 gallons per minute). Pre-fabricated lift stations generally have capacities of up to 38,000 liters per minute (10,000 gallons per minute). Centrifugal pumps are commonly used in lift stations.

A trapped air column, or bubbler system, that senses pressure and level is commonly used for pump station control. Other control alternatives include electrodes placed at cut-off levels, floats, mechanical clutches, and floating mercury switches. A more sophisticated control operation involves the use of variable speed drives.

Lift stations are used to reduce the capital cost of sewer system construction. When gravity sewers are installed in trenches deeper than three meters (10 feet), the cost of sewer line installation increases significantly because of the more complex and costly excavation equipment and trench shoring techniques required. The size of the gravity sewer lines is dependent on the minimum pipe slope and flow. Pumping wastewater can convey the same flow using a smaller pipeline size at shallower depth, and thereby reducing pipeline costs.